Menu

Contact info

-

Our office

Binh Duong Boulevard, Ward 3A, Thoi Hoa Ward

Ben Cat Town, Binh Duong Province

-

Phone

0933.384.579

0274.3555108 - Email sales.phutin@gmail.com

What is an oxygen generator?

Oxygen generators separate oxygen from air so that the gas can be fed into industrial processes immediately or stored in pressure vessels. Oxygen generators are used in a variety of industrial applications, from gold mining to aquaculture to life support.

Normal ambient air is made up of 78% nitrogen, 21% oxygen, and other trace gases such as argon and CO2. To remove nitrogen and other gases, oxygen generators are used.

The smallest oxygen concentrators may be no larger than a can of soda, while industrial oxygen concentrators can be as large as a bus. However, all oxygen concentrators have the same purpose: to provide a safe supply of pure oxygen gas.

Businesses that need oxygen in large quantities often start by purchasing oxygen tanks from other companies. If demand is large and continuous, businesses can save costs to purchase their own oxygen generators and produce oxygen on site. While the initial investment cost is quite large, the cost per cubic meter of oxygen produced is 1/3 to 1/2 compared to buying oxygen in bulk, thus being more cost-effective in the long term.

An example of this is hospitals introducing oxygen into patient rooms. Instead of buying stock oxygen tanks, most hospitals have one or more industrial oxygen generators in the building.

Types of oxygen generators

Swing pressure adsorption oxygen generator

- Pressure adsorption (PSA) is the most common method for producing oxygen on an industrial scale. The PSA gas generator separates nitrogen from the surrounding air inside a pressurized tank filled with Zeolite. Zeolite is a natural or artificial mineral that acts as a “molecular sieve”. It is this ability to “sort” molecules by size that makes zeolites so useful. Larger nitrogen molecules are absorbed by the sieve material while smaller oxygen molecules pass by and are collected. The pressure is then released, the nitrogen molecules are vented to the atmosphere, and the tank is pressurized again.

- Using PSA will create 90-95% oxygen. Further purification can be achieved by repeating the process until more than 99% “pure” oxygen is produced.

Refer immediately to Oxymat 95% purity oxygen generator

- As a side note, the PSA process can also be used to generate nitrogen by collecting nitrogen molecules and releasing oxygen gas. PSA is also used in the large-scale commercial synthesis of hydrogen used in oil refineries and in the production of ammonia for fertilizers.

A special type of oxygen generator often called an oxygen concentrator is used as an alternative to oxygen tanks for home health care. Although the machines’ upfront cost is more expensive than oxygen tanks, they are safer than bottled oxygen and over time less expensive than having oxygen tanks delivered to your home.

Membrane oxygen generator

Membrane oxygen generators give us a stream of compressed air through semi-permeable materials that allow specific molecules to pass through. Under pressure, smaller oxygen molecules pass through the membrane, are filtered out and collected, leaving a stream of nitrogen flowing out the opposite end of the membrane. Although membrane generators are not as common, they are considered more reliable because they have no moving parts that can fail.

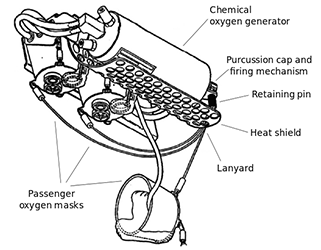

Chemical oxygen generator

A chemical oxygen generator is a device that releases oxygen by a chemical reaction. A vessel containing inorganic salts called “superoxide” or sodium chlorate is ignited. As they heat up, they produce oxygen until the compound is consumed.

Because of their long shelf life, stability, and small size (about the size of a soda can), chemical oxygen generators are used in commercial aircraft. Mounted on the seat, each generator can produce enough oxygen for 2-3 masks in 10-20 minutes. A similar device is called an oxygen candle. It operates on the same principle of releasing oxygen by heat and is used as a safe personal oxygen supply in mines, submarines and on space stations.

Oxygen generator application

Some common applications of oxygen generators

Oxygen supplied for medical use

Medical grade oxygen used in hospitals or for home health care is certified to meet the United States Pharmacopeia (USP) XXII Oxygen 93% Monograph. The USP requirement is an oxygen level of 90 to 96% pure with the remainder made up of argon and hydrogen. No more than 300ppm CO2 or any other gas or molecule is allowed.

Generate oxygen for fish farms & aquaculture

Like humans, fish and other marine animals need oxygen to survive. With the popularity of fish farms, “farmers” must ensure their animals are properly oxygenated to survive. Before raising fish on an industrial scale, farmers may fence a natural water area at the edge of the lake to raise fish and make fishing more convenient. With industrial oxygen generators, farmers now have the ability to raise fish in artificial lakes containing oxygenated water. The benefit to the farmer is higher stocking density in a smaller area and faster fish growth.

You may be interested in Signs to recognize when fish lack oxygen and how to fix it

Wastewater treatment

In wastewater treatment plants, oxygen generators are used to provide additional oxygen to bacteria to help biodegradation occur. Bacteria break down sludge into CO2 and water faster if oxygen is added during the process.

Steel industry

Industrial oxygen generators are used in the steelmaking process in a number of ways. Oxygen furnaces are used for decarburization, the process of reducing carbon in a metal while in a molten state. Oxygen is also used to speed up melting in the furnace and reduce scaling when heating the furnace.

Gold mining

Industrial-scale gold mines use oxygen generators in the cyanide leaching process. The sodium-cyanide solution is mixed into crushed gold-bearing rock with oxygen to release the gold from the rock.

Welding and cutting metal with oxygen gas

Oxyacetylene metal cutting and welding uses liquid fuel and oxygen to increase the flame temperature so that the metal is molten at the point of the welding tip. This melt can be used to weld or cut metals.

Blowing glass

Like welding, glassblowing requires high temperatures to melt the glass. Oxygen is used to increase the temperature of the flame both in the oven and the torch used to shape the pieces of glass.

Production of paper and pulp

Delignification is the process of extracting lignin from plant material in one of the steps necessary to create paper from trees. Large amounts of oxygen are needed during this process, as well as several later steps in pulp and paper production.

Leave A Comment